-

-

Nanhera Anantpur Puhana Roorkee - 247688 (Uttarakhand)

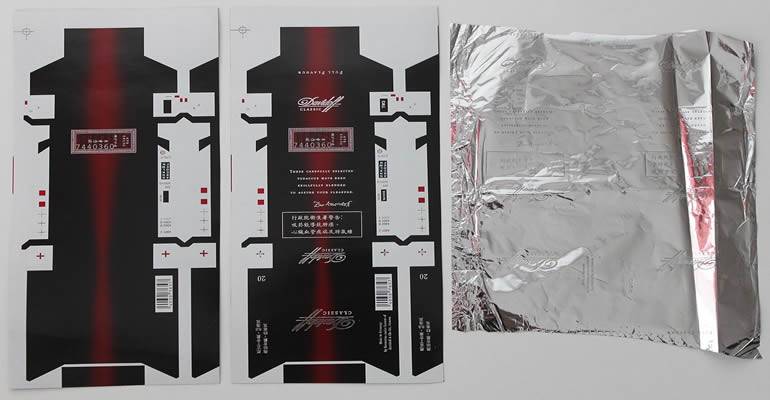

Hot/Cold Foil Stamping or Embossing

- Printing & Finishing

- Process Color Printing

- Pantone Spot Color Printing

- Metallic colors printing

- Color tinting & die cutting

- Holes punching & Fan folding

- Tag Designing & Cutting

- Perforation Cutting

- Gloss & matt laminating or varnishing

- Hot/Cold Foil Stamping or Embossing

- Pattern coated glue

- Serial number printing

Hot/Cold Foil Stamping or Embossing

Hot Foil Stamping is an efficient system that takes advantage of technological advancements. Dies can be customized to capture even the most intricate details. The foil itself, although we think of it as metallic, actually comes in a variety of colors, finishes, and textures. You can also combine hot foil stamping with embossing or debossing in a single pass to add a literal dimension to your cartons or printed materials.

Whether in sheet-fed lithographic or flexographic printing, cold foil can be applied inline. Foil is dispensed from a roll mounted inline and laid over the substrate, which has a UV adhesive printed in the desired pattern. A pressure roller seals the foil to the sheet before exposure to a UV lamp cures the adhesive and locks the design in place. You can customize foils by applying CMYK or PMS colors to traditional silver or gold foils

One of the biggest differences between the hot foil stamping and cold foil techniques is right in the terms. The ‘hot’ refers to the heat and pressure necessary in that process, while cold foil relies on ultraviolet light rather than temperature.

Numerous industries rely on foil to enhance their folding cartons, including food and beverage, beauty and cosmetics, cannabis, fine wine, craft beers, and spirits. Food and beverage brands employ foil to hint at the premium quality of their products.