-

-

Nanhera Anantpur Puhana Roorkee - 247688 (Uttarakhand)

About us

Printing Sticker Labels Comapny

committed to providing our customers with exceptional service.

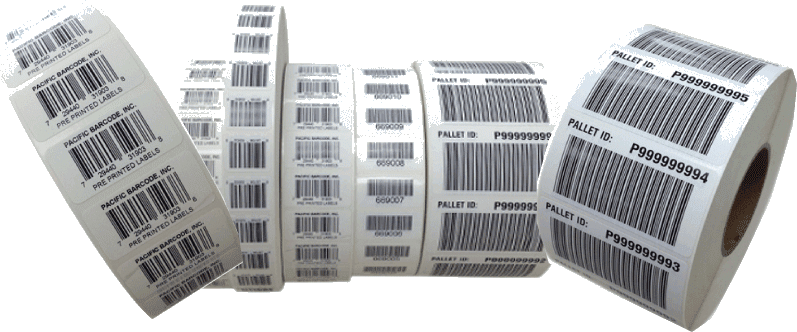

I would like to introduce our company Essential Graphics that is been in business of Printing of Sticker Labels Starting this year. We are backed by a state-of-the-infrastructure, which is aptly managed by our team who are well- versed with working of the concerned domain and trends prevailing in the market.

They completely understand our organizational needs and make effective and utmost utilization of available resources. We have the capacity of 1 Crore Labels per day with the facility of UV as well as of aqua base printing with on-line cold foil and off-line hot foil stamping options by Automatic Flexographic Printing machine with 8 colors round printing, glazing, automatic infrared drying, fill covering and rewinding process.

00

+15 Service Worldwide

100

+Experienced Person

00

+Years Of Experience

00

+Wordwide Clients

Our Mission

our mission label's mission is very simple which is to provide quality products at a competitive price and this has been our principle even since 2022 when we started. Although technologies, markets, customer expectations have changed but our principles have never changed. produces labels and supplies label supporting equipment for both domestic and oversea markets As a supplier, it is our policy to ensure that our products and services adhere to contractual specifications, applicable statutory and regulatory requirements and satisfy the customers in terms of consistent quality and timely delivery.

We are committed to enhance customer satisfaction through effective application of the quality management system, including processes for continual improvement.Our Management will assume accountability for the effectiveness of the ISO9001 quality management system and for ensuring that the resources needed for the quality management system is available. Customer needs and applicable statutory and regulatory requirements are determined, understood and consistently met. Apply risk-based thinking to determine the type and extent of control appropriate to major external providers and internally provided processes, products and services.

Paper Quality Check Inventory

Exhaustive checking procedures for incoming material, in process material and out going material 100% automatic control available on rewinding machines Scuff tester, peel tester and Color measurement capabilities Accelerated ageing Barcodes and 2D codes verification. Label surface slip Advanced vision inspection system Tests Conducted: Scuff Test Tape Test Coin Test Ink Rub Test.