-

-

Nanhera Anantpur Puhana Roorkee - 247688 (Uttarakhand)

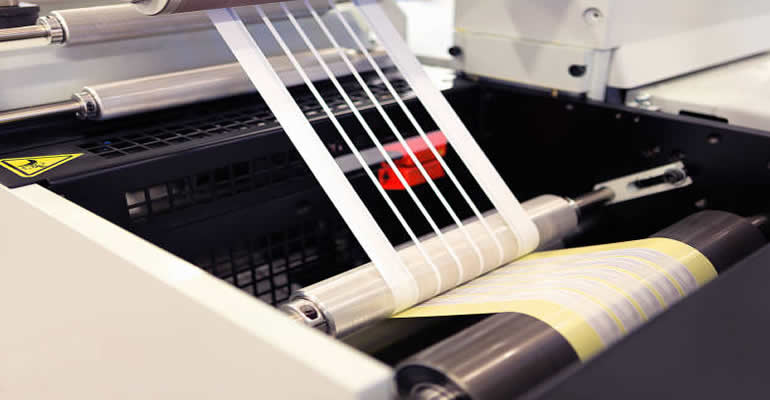

Color Tinting & die cutting

- Printing & Finishing

- Process Color Printing

- Pantone Spot Color Printing

- Metallic colors printing

- Color tinting & die cutting

- Holes punching & Fan folding

- Tag Designing & Cutting

- Perforation Cutting

- Gloss & matt laminating or varnishing

- Hot/Cold Foil Stamping or Embossing

- Pattern coated glue

- Serial number printing

Color Tinting & die cutting

The die cutting procedure functions very similar to a cookie cutter…where a preformed shape with a sharp perimeter edge is forced through a substrate using pressure.

The thin steel blades, known as rules, can be formed into a variety of interesting shapes to add creativity and uniqueness to printed pieces. The blades are engineered to produce clean and accurate cuts, ensuring that each custom shape is consistent in size and quality.

In the printing industry, Die Cutting refers to a process that uses sharpened steel blades to cut specific shapes, patterns, and designs in paper, cardstock, or other materials.

In addition to adding a custom-shaped perimeter to printed pieces, die cutting can also be used to cut shaped holes or "windows" within the printed pieces. The most common base material is a strong and stable wood, such as birch or maple. Nylon and composite boards are sometimes used as well.